Starter and Solenoid Removal

So you need to remove the starter assembly from your car. If you narrowed your problem down to the solenoid, you could try and just remove the solenoid by itself - there are 3 philips flathead screws holding it to the starter motor housing, but I did not see that possible. The access is difficult, the screws will be on very tight, and it is really easy to shear off the philips head pattern. In fact, even when I removed the starter from my car, I had trouble removing the solenoid screws. If you still want to try removing just the solenoid, follow the steps below as far as needed to get enough access to the philips screws and then use a rachet with an appropriate philips driver. Press hard and at the right angle, or you will shear off the bolt pattern. (Regular screwdriver did not work for me).

Take the following steps to remove the starter from the engine:

- Disconnect your battery.

- Remove three main airducts (for turbo cars): air filter to turbo inlet (but no need to disconnect the rubber elbow which houses the dump valve), turbo outlet to intercooler, and intercooler to throttle body. If you have a turbo, I suggest covering up your exposed turbo ports immediately to prevent dirt from falling in

- Remove air filter and AMM (air mass meter) in one piece.

- Disconnect TPS (throttle position sensor) from its wiring to avoid damaging it.

- Disconnect some air ducts from the throttle body as needed to be able to move the wiring around enough to get good access to the black plastic cover sitting over your clutch and flywheel. I ended up disconnecting hoses from the dump valve (turbo), the AIC (automatic idle control) valve, and the crankcase breather pipe, if memory serves.

- Disconnect one grounding point on top of the cylinder head which has one black wire and one orange wire attached to it. This will help you move your wiring more freely to avoid inadvertantly damaging connections.

- Disconnect any cables/connections on the back of the starter. Those include battery and alternator cables at terminal 30 and the plastic spade connector at terminal 50. Also, disconnect similar spade connectors from throttle microswitch under the throttle valve pulley to get the wiring out of the way.

- Remove any bolts on the driver's side of the plastic clutch/flywheel cover . On cars with manual transmission, there are two bolts on the driver's side of the cover, the lower one, securing the cover to transmission housing, and the upper one, securing the cover and positive battery cable holder to engine backplate near the starter.

- Remove the throttle body support arm which extends from the back engine plate near the starter to underneath the throttle body. First, partly undo the throttle body nut but do not remove it yet. It is a 12-mm or a 13-mm nut, and it is likely to be on very tight. Use a rachet and a socket to avoid damaging the nut. To remove the support arm from the engine plate, I pulled the wiring over the throttle body to get it out of the way and pulled the plastic cover away to the left to expose the 14-mm bolt head enough to put a socket on it. Your engine bay might now look something like this:

- Remove the starter mounting bracket on the back of the starter motor housing from the engine block. It is important that you unbolt this bracket from the engine block and not from the starter, else you will not be able to remove the starter. The picture shows where the mounting bracket bolts on to the engine block (empty bolt holes).

The large coolant hose makes it a bit tough to access those 2 bolts. These bolts will need a lot of torque to undo. I first tried using a box end wrench, but it was useless: the bolts didn't even budge without enough leverage. Then I switched to rachet, which takes up more space but seemed to be the only way for me. You will need to pull and lift that coolant hose to give you enough clearance to get a rachet in there. It will take a little finesse, but there is enough room to pull and lift the hose without putting much stress on it. When I was doing this, some coolant spilled out of the crankcase breather pipe. I am not sure why. - Remove the nuts from two 14-mm bolts in the engine plate that are holding the starter motor housing onto the engine plate. Pull the black plastic cover out of the way and use a 14-mm box end wrench on the bolt heads to loosen them. After that, the nuts should come off easily. Leave the bolts in place and carefully slide the starter assembly out under the throttle body. The pictures below show the engine back plate with starter bolts left in place and the space where the starter sits:

Repair

SolenoidNow that the starter is out, there are several things you could do with it. If you narrowed the problem down to the solenoid (most common cause), you need to simply replace it. To remove the solenoid, first remove the thick wire from the back of the solenoid that leads into the starter motor housing. Then, remove the 3 philips flathead screws. Use a rachet with a philips head driver here and press down as hard as you can. Anything else will shear off the philips pattern, as I found out from experience. In fact, I had to drill all three screws out. It isn't very difficult because you only need to drill out the head of each screw you messed up, but make sure you drill pilot holes of increasing sizes for every screw. This is what the inside of the solenoid looks like:

The cylindrical space inside the solenoid (above) is filled by the plunger (below). There is a spring that is fitted between the bottom of the plunger and the gold-plated button inside the solenoid (shown above). The plunger hooks onto a lever inside the starter motor housing

which is used to engage the starter motor gear into mesh with your flywheel. Often, just thoroughly cleaning the plunger and inside the solenoid will solve the problem of a sticking solenoid.

Now, let us check the contacts on the back of the solenoid:

Clean all these contacts. In its unenergized state, the plunger inside the solenoid is all the way forward, the gold-plated button inside the housing is depressed, and there should be an open circuit across terminal 30 (battery power supply) and "terminal 70" (starter motor power cable). At the same time, there should be a closed circuit across terminal 50 and "terminal 70" with some small resistance. This is where the solenoid draws its earth: through starter motor brushes and windings, not through solenoid housing. When power from the ignition switch flows to terminal 50, the electromagnetic force causes the plunger inside the solenoid to retract. When the plunger retracts, it moves the starter gear forward to engage the flywheel

and presses the gold-plated button inside the solenoid housing (see picture above), which creates a closed circuit across terminal 30 and "terminal 70" and makes the starter motor spin. After you clean the plunger, the insides of the solenoid housing, and its contacts, re-attach it to the starter motor housing with 3 bolts and re-install the wire strap that powers the starter motor from the solenoid. To test, use jumper cables to connect a positive battery terminal to terminal 30 on the solenoid and a negative battery terminal to the front of the starter motor housing. Now carefully and briefly power up terminal 50 by connecting a jumper between terminal 30 and terminal 50. Caution: if the starter motor will spin, it will generate large amounts of torque and will be difficult to hold in place, so before doing this test, lay it against the wheel of your car and step on it. Do not run this test for more than a couple seconds, or you will damage your starter motor!

If this procedure does not fix the problem, solenoid windings may be damaged or its contacts could have eroded. Replace the solenoid.

Starter Motor

Since you removed the starter from your car, it might be a good idea now to take it apart and clean/lubricate the mechanism of your starter motor (but only if you found your starter motor to be healthy during the diagnostics!) It is an easy procedure, but prepare to get really dirty.

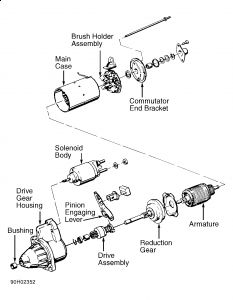

First off, unbolt the solenoid from the starter motor housing and set it aside. Let's have a look at the back of the starter motor housing:

As circled in red in the picture above, the two rods that hold the starter motor housing together each have a 7-mm nut on them. The nuts are offset into the washers. You will need either a 7-mm deep offset box-end wrench or a 7-mm socket that has a hole in it large enough for the rod to slide through it. For me, 7-mm socket with a rachet worked just fine. Loosen the nuts just a little for now, perhaps by a turn or so. Unscrew the two philips screws and gently remove the cap from the back that you see in the picture. There will be a washer and a locking ring-clip sitting on a shaft. To take the ring clip off, push on it from its open end and as you do it, wedge a screwdriver blade on the opposite side to pry it off. It should come off fairly easily. Now, undo the two rods all the way and take them out, but rest the front of the housing on the floor so that it does not drop. Pry the back cover off, and you will see something like this:

That's 4 small magnets with the winding strap attached to them, sitting on the set of small brushes. At any circumstances, do NOT allow the ring that houses the 4 magnets to slide off the brushes. It is possible to re-install it if that happens, and I was successful at it, but it requires a lot of patience, strong fingers, and plenty of manual dexterity. It is easier to just not remove it.

Now, let us remove the front of the starter motor housing. Lay the motor housing on its side, and carefully start wiggling the front section. You will see a rubber piece where the lever arm driven by the solenoid is housed. Pry it off carefully, as well as the orange plastic pivot attached to the lever arm. Once free, you will be able to slide the front of the housing off, exposing something like this sticking out the front:

Grab this assembly, and pull on it to decouple it from the rest of the assembly, and it will come off in one piece, shown above. That's ring gear and clutch gear. Remember the location of the off-white plastic housing you see here with respect to the main motor housing (black). I believe there are flat divots to match. This is another shot of this ring gear assembly from the other end (with black plastic cap covering ring gear removed):

There you can see that flat divot on the off-white plastic housing that I mentioned. It should align with the orange plastic pivot for the lever arm, the rubber piece, and the main motor housing. Now that ring gear is off, you will see starter motor and its pinion (where my hand is, in front of the coil windings):

So now, you can connect all the dots of the inner workings of your starter motor. Play with the ring gear assembly to see how it works - it's fun! In the picture above, you can see that I took the motor out of its housing, but there is absolutely no need to do that. I did it out of curiousity and to clean things up a bit, but it is not worth the trouble really.

At this point, inspect all the gearing and see if it is in good condition. I bought some nice, viscous Lithium grease and lubricated all the gearing to make it smooth and try to prolong its life. That includes motor pinion, ring gear, clutch, and front starter gear and shafts. Grease the gearing liberally and work the gears through the grease, but make sure you wipe away any excess grease. Make sure the clutch is well-lubricated, but that the excess grease does not make its extended and retracted positions stick! Same for the outermost gear that engages flywheel. Clean up whatever you can, but be especially careful with the coil windings of the motor because you do NOT want to scrape any insulation from those wires.

Now, we can put everything back. I will assume you did not take out the motor from its housing. If you did, you know what the force of those magnets is, so when you put the motor back into its housing, hold in the ring assembly of those 4 magnets on the end so it does not slide out while you put the motor back in. Put the black plastic cap back on the ring gear and slide the ring gear assembly back onto the starter motor pinion, making sure that the divots in the housings align, as I pointed out before. Now, you can put the front part of the starter housing back on, taking care to align its bolt holes with the two threaded rods we took out earlier. Put the rubber piece in the housing and press the orange plastic pivot into it to secure the lever arm. Screw the rods in by hand and turn the motor to rest on the front of its housing and re-install the back plate, the washer, the ring clip, and the cap, securing it with two philips screws. Now tighten the rods with a 7-mm socket and a rachet. To reinstall the solenoid, hook its plunger into the lever arm and slide solenoid housing onto the plunger, remembering to put the spring under the plunger (or your starter motor may not disengage from the flywheel!). Re-install 3 bolts to secure solenoid housing to starter motor housing. Installation of the starter back into your car is the reverse of the removal procedure outlined above.

Oh wow... I just discovered my starter needs to be replaced and yours was the first hit on my search -- and you just posted this yesterday. What timing! One question, you mention I can just replace the solenoid if I have narrowed the problem down that far. What kind of diagnostics can I do to determine that, bearing in mind that I'm a software guy and lucky to figure out one end of a screwdriver from the other three times out of five? The only reason I know it's the starter is my wife told me that's what the clicking sound means when the battery is charged and I try to start it. I do have a voltmeter thingie, for what that's worth.

ReplyDelete